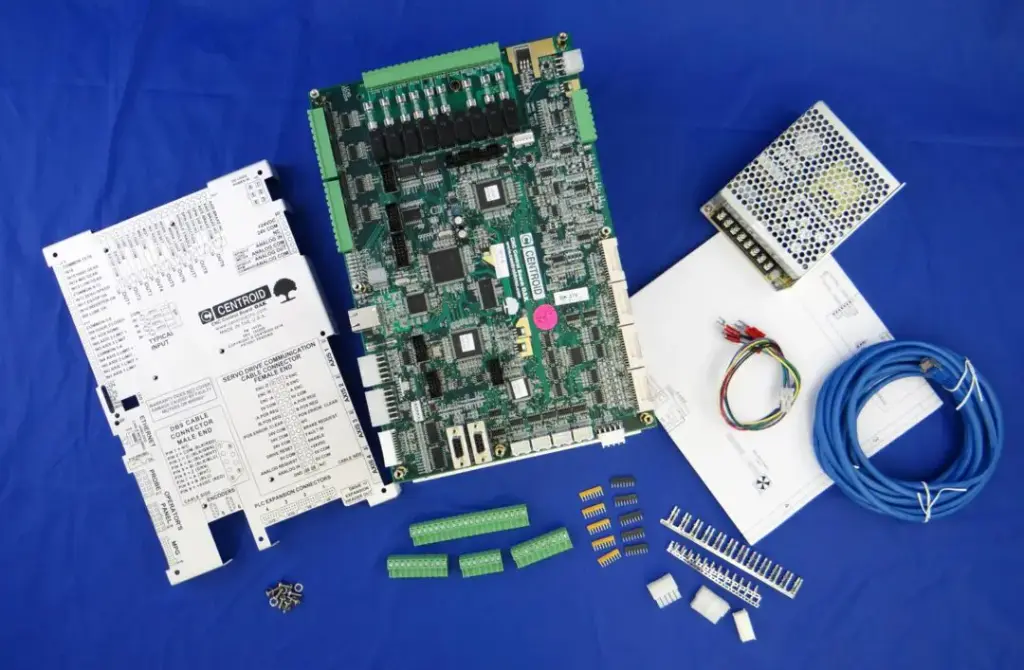

Oak Board CNC Controller w/ Software Package

Centroic Oak Motion Control Board

Features:

Built in Motion Control CPU

Mill and Lathe CNC software

Reliable Ethernet communication with CNCPC

Runs on Windows 10

Compatible with CAD/CAM systems

Runs Standard G & M Codes (see list in operator manuals)

4 Mb G code program size (unlimited optional)

True G-code back plot graphics w cutter comp moves

2000 line accell decell look ahead

1200 blocks per second

Feed rate override operator variable 0-200% at 1% increments

Plug and Play dedicated MPG port

Rapid rate override

Spindle Control. on/off cw/cw, speed w/override

12-bit analog output 0-10 VDC for VFD control

16 optically isolated inputs, user configurable

9 fused relay outputs, user configurable

Centroid Operator control pendant compatible

Six Encoder Inputs

Single 24 vdc logic power input

Spindle Encoder RPM display

Simple Menu Driven Operator Interface

Stop and Restart Job at any point

Tool Check, Jog and Restart at any point

Cutter Compensation

Conductive touch probe compatible

Kinematic touch probe compatible

Dedicated Touch Probe port

6 WCS G54 - G59 (12 more optional)

4th axis software (both G code and Conversational)

Lube Pump control (user configurable to match pump type)

MDI mode with recent command memory

Programmable Auxiliary Function keys

Multiple Language Support

Stock PLC programs

User editable PLC programming

Part counter, Time, Time estimation

Simple Future Software updates available

G code editor

Utility Menu

Backup and Restore CNC config

Message Display and Logs

True Closed Loop CNC operation

Unlimited Program Storage (only limited by hard drive size)

Large easy to read DRO display

Menu Driven Part setup

Menu Driven Tool setup

Menu driven machine configuration setup

Fill in the blank Setup Menus

Run Menu

CNC control configuration menu

Restart Job Automatically

Any axis can be linear or rotary axis

G-code smoothing (user adjustable)

Auto Home to switch, user selectable direction per axis

Jog to Home or Home to Marks

Software Travel Limits (+ and - directions)

User configurable Slow, Fast, Max rates

User configurable axis motor acceleration

Backlash compensation

Gcode backplot checks work envelope

G code backplot shows true cutter comp moves

Vary part backplot speed and pause w/ G-code line display

Real Time Part Graphics, shows tool position while running

Optional Stops

Subprograms and Macros

Engraving compatible (short vector g code no problem)

Threadmilling (Mill)

Run in Inch or MM mode

Tool Library

Long part names

Drilling and Tapping Cycles

USB and Network Drive Compatible

Keyboard Operator Control panel emulator,

Xkeys USB control pad compatible

Tool Life Management

Ballscrew mapping table

Control relays and contactors thru Manual or Program control

User configurable custom DIY M-codes

Canned Cycles

Constant surface speed (lathe)

Threading (lathe)

Profiling with auto cleanout (lathe)

Lathe canned cycles (thread, groove, chamfer, cutoff,turning diameter and end face,

Scale input for DRO positional display of a manual axis

X/Y axis Deskew

Coordinate System Rotation