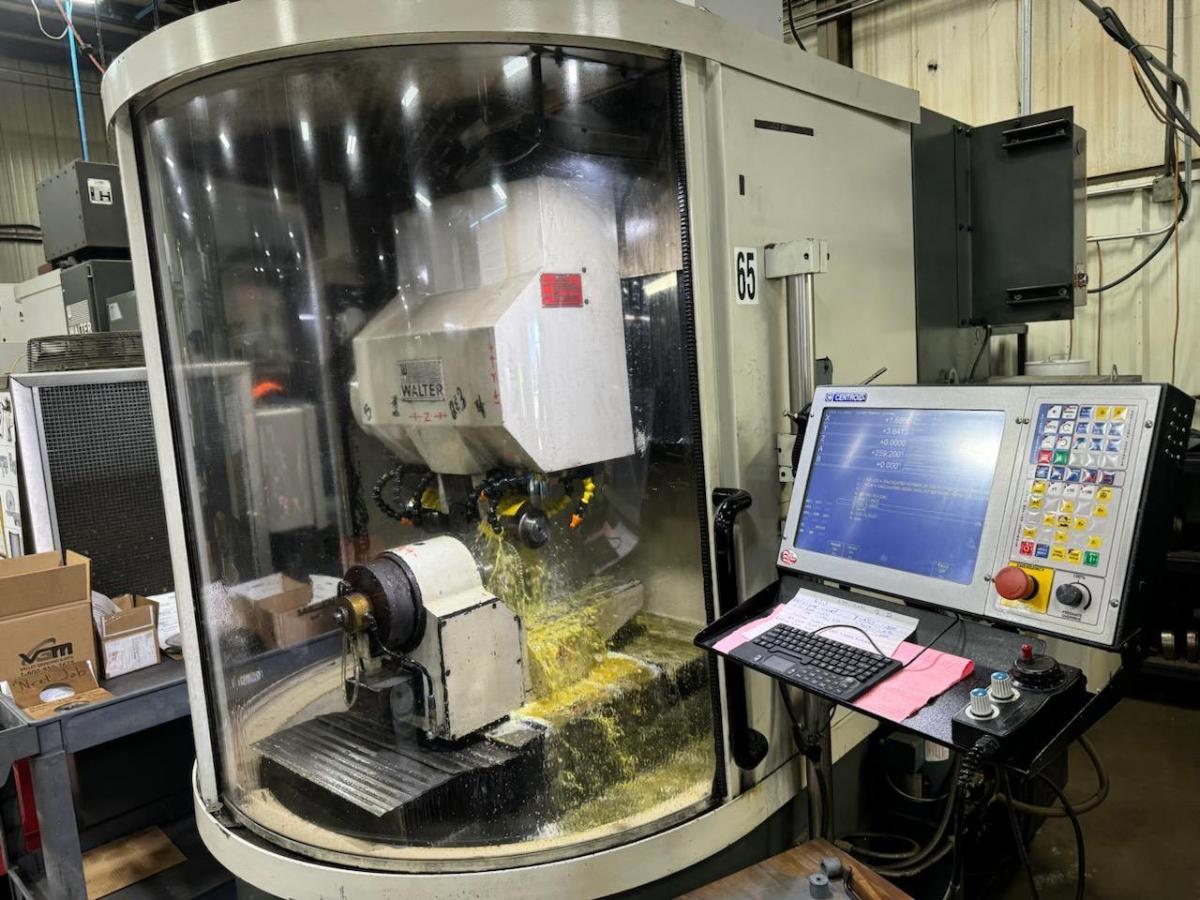

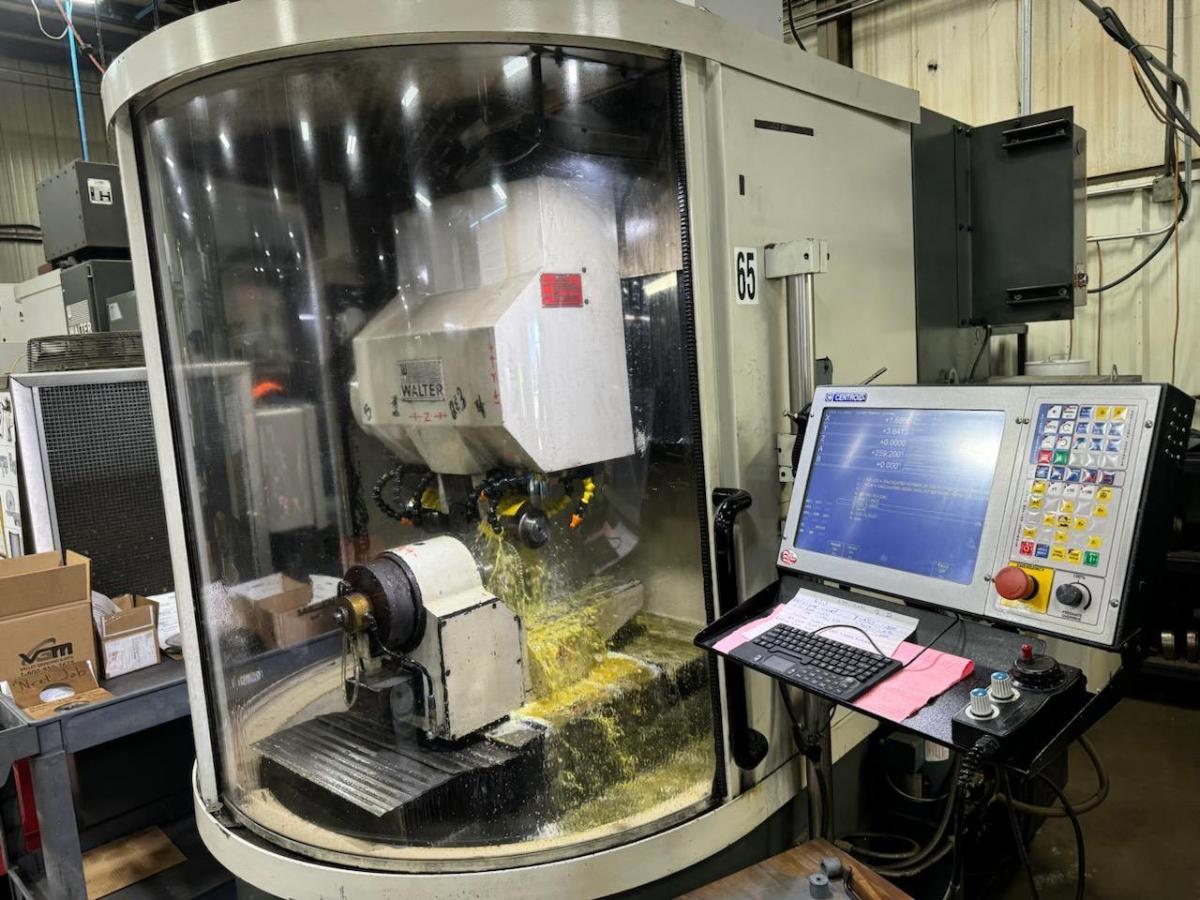

Walter Helitronic Power 400

Turnkey Project

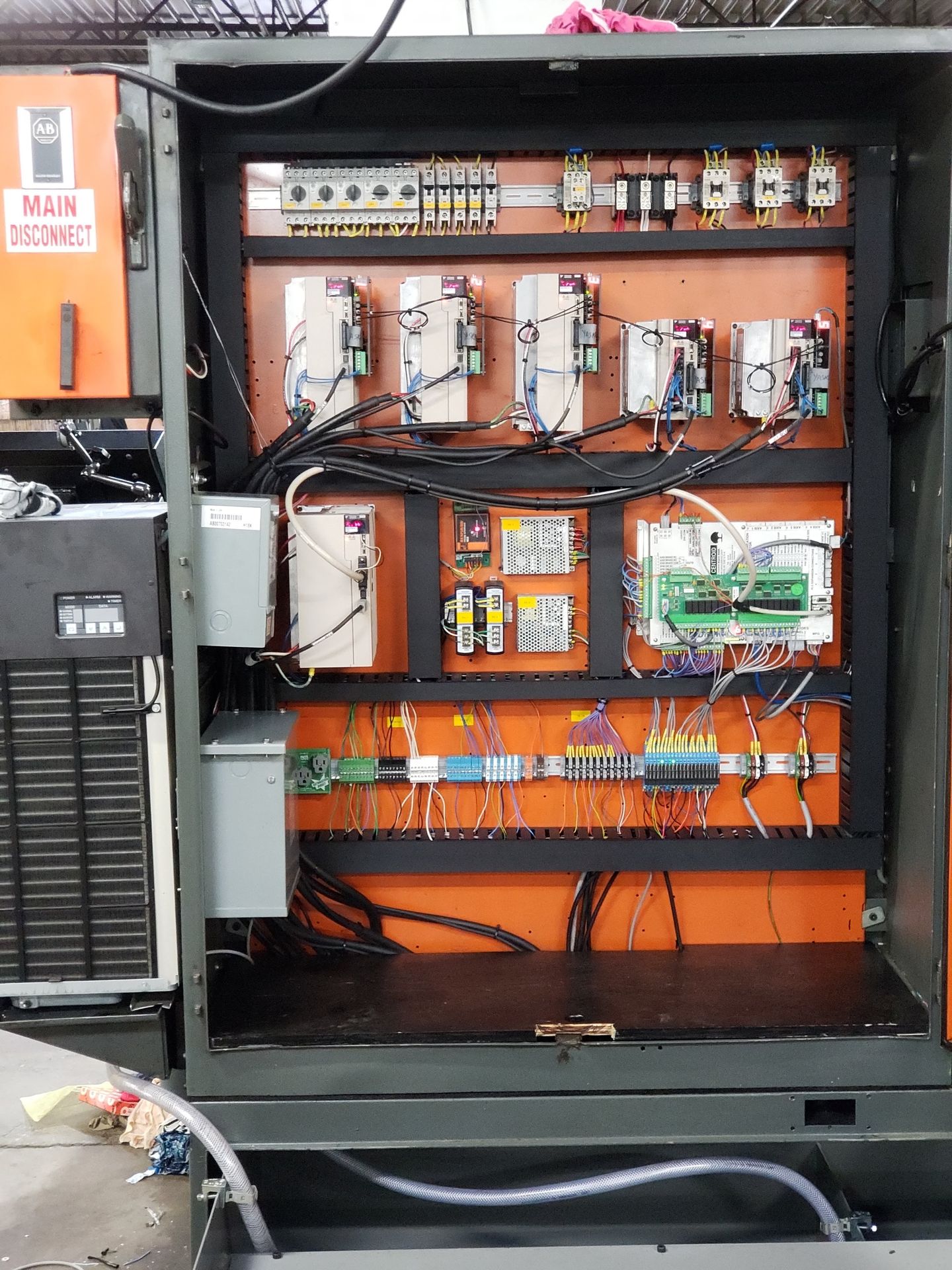

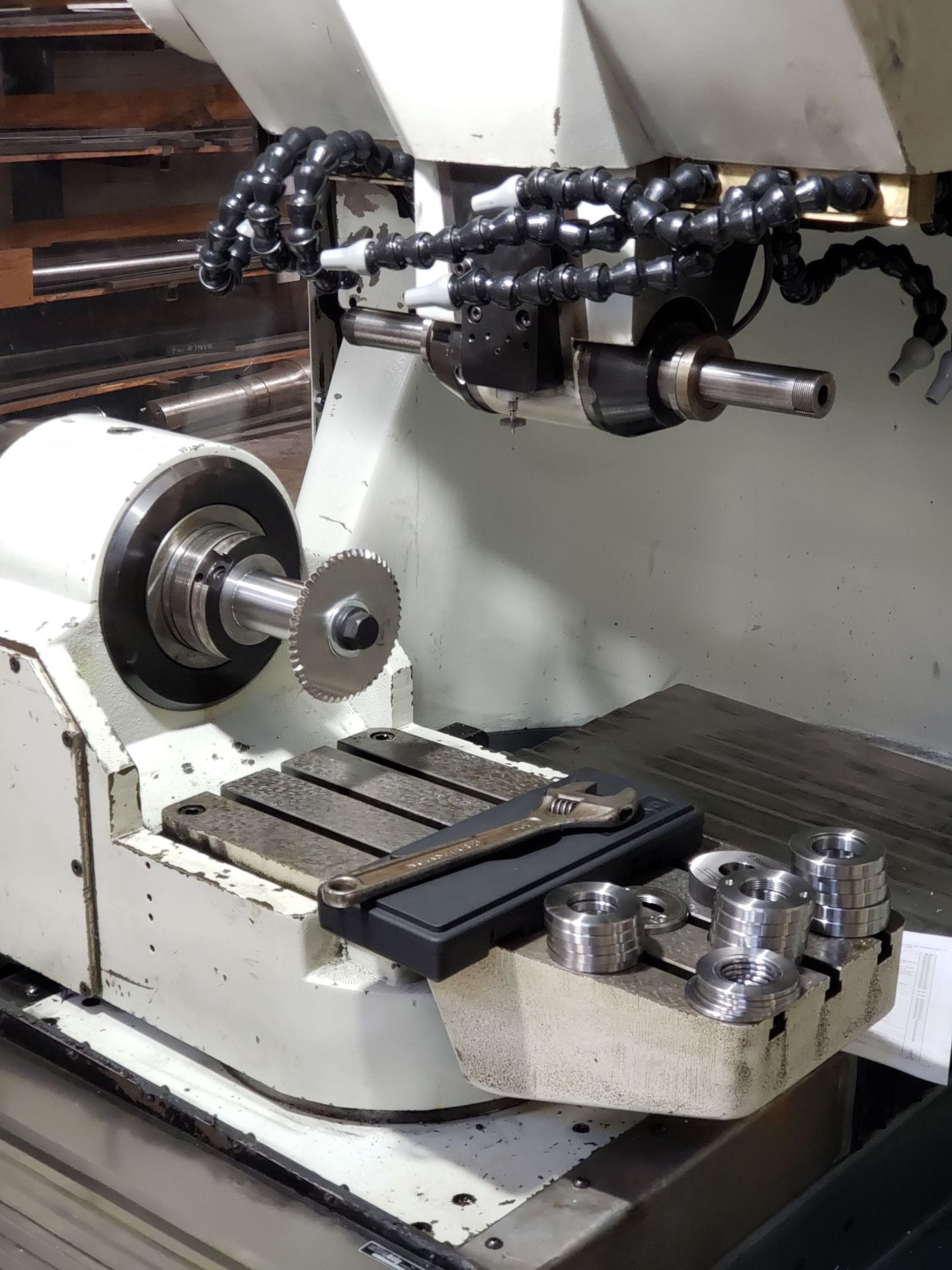

This Walter Helitronic Power400 was retrofitted with the Centroid fully closed loop control system, Custom part probing routines. The customer was looking for a machine that could be dedicated to grinding a specific type of part. The customers current solution was an old Walter tool grinder that required the operator to setup each part individually and modify the program manually every time resulting in extremely long part processing times per part. We were able to get our hands on a Walter Helitronic that needed a new control system already. The mechanicals of this machine were still in excellent condition. We was able to install the Centroid Control system with integrated custom probing that would identify which sized part had been installed as well as detect the number of teeth on the part allowing for a single program that would be capable of grinding new parts or regrinding old parts simply by loading the part and pressing cycle start. This ultimately lowered the cycle times to just a few minutes per part. The machine ended up being so efficient that the machine was able to run through there existing work load and more resulting in open time to perform other tasks on this machine.